Mold Maintenance Products

Chem-Trend has developed a broad portfolio of Lusin® brand mold maintenance products for the thermoplastics industry. This portfolio is the result of nearly 70 years of Lusin® heritage, working directly with thermoplastics processors, understanding their challenges, and creating products that address their shop floor challenges.

Our mold maintenance line encompasses:

- Cleaners (including Degreasers)

- Lubricants

- Protective Agents (including Rust Preventatives)

VIDEOS

How to Use Lusin® Products to Clean and Degrease a Disassembled Mold

Discover the proper technique for applying Chem-Trend’s Lusin® mold maintenance products through a detailed demonstration with a Chem-Trend expert.

How to Care for a Built-in Mold: Clean, Lubricate, Protect and Release

Learn the proper application techniques to keep your built-in mold clean, lubricated, and ready for a release agent.

How to Maintain and Degrease a Built-in Mold

Discover the proper technique for applying Chem-Trend’s Lusin® degreaser to clean wax- or oil-based products from your injection molding machine for improved operations.

NEWS

RELATED THINKING

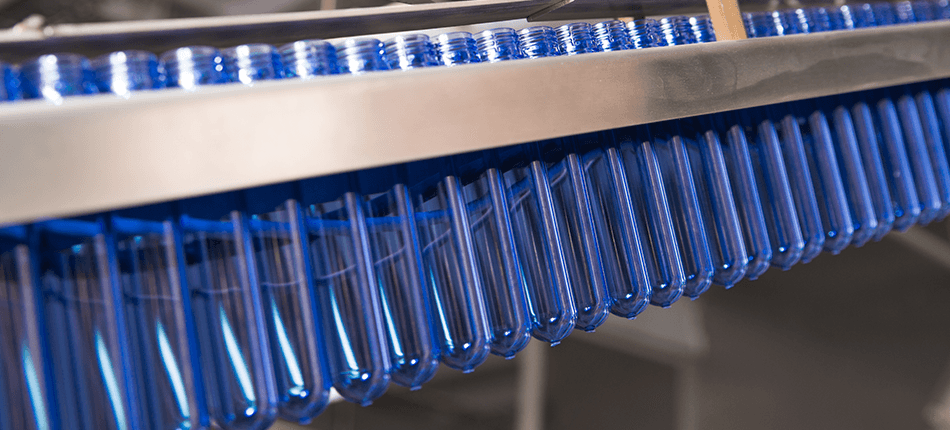

Minimising Blockades in PET Bottle Manufacturing Lines

PET Packaging Aids for the Food Processing Industry

BROCHURES

Lusin® Mold Maintenance Products and Release Agents

Chem-Trend cleaners and degreasers, protective agents and lubricants and release agents maintain tools and machinery in the thermoplastics processing industry. Find more information in our online digital product catalog of Lusin® Mold Maintenance Products and Release Agents.

FAQs: Cleaners and Degreasers

Learn more about mold cleaners, surface cleaners and degreasers for thermoplastics applications and get answers to frequently asked questions.

FAQs: Lubricants

Looking for answers about lubricants for thermoplastics processing applications? Learn more about frequently asked questions and the answers you need.

FAQs: Lusin® Product Portfolio

Learn more about our Lusin® portfolio of mold maintenance products and get answers to frequently asked question.

FAQs: Protective Agents

Find answers to your frequently asked questions about protective agents for thermoplastics processing applications.

Vitamins for Food Packaging

The new Lusin® Lub O 32 F offers competitive advantages to thermoplastic moulders, improving processing efficiencies. As a hybrid material, with proven power as both a release agent and a lubricant, it eliminates the need for multiple products. In the manufacture of PET food packaging, it significantly improves the preform and film production stages.

Lusin® – Professional Products for Thermoplastics Processing

Download our thermoplastic processing product brochure to find out which of our Lusin®Brand release agents will work for your application.

FAQ

Mold cleaners are principally designed to dissolve polymers, with the sole exceptions being PE and PP.

Degreasers (surface cleaners) are designed to remove buildup of oils, waxes, and pastes.

It is not possible to dissolve polyolefins. However, when cleaning a mold, the polymer is typically not causing the main problems. Instead, it is additives, pigments, and paints that are building up in the mold and need to be removed. Mold cleaners are formulated to attack those specific problems to fully clean a mold.

The viscosity or MFI (Melt Flow Index) of some engineered polymers can disrupt the passage of air through the venting system of the mold. The application of a mold cleaner to the air venting system during the production process can often solve this issue and avoid the need to remove the mold from the machine for cleaning purposes.

Lusin® Clean L 23 F and Lusin® MC1718 evaporate too quickly at temperatures above 75°C/167°F and cannot remain on the surface long enough to dissolve the polymer residues.

Yes. Lusin® Clean 101 F can be used effectively on hot molds with a maximum surface temperature of 130°C/266°F.

No. Lusin® degreasers (surface cleaners) will not attack plastic. They are safe to use for removing oils and waxes from plastic parts.

Not only does corrosion destroy the surface of the mold and tooling, but it has a damaging impact on the produced part, too. To prevent from such damage, molds and tools should be maintained on a regular basis and should be securely protected against corrosion and oxidation by use of a specialised mold protectant — particularly if they are not used for a longer time or are stored.

There are two different kinds of mold protectants: anti-corrosion agents that are oil-based and those that are wax-based.

Oil-based mold protectants:

- Oil-based mold protectants are fairly fluid and are therefore able to creep into the tiniest spaces that are most difficult to access, such as recesses and undercuts.

- Oil-based anticorrosion agents dispel moisture and form a temporary protective layer that can last for several months.

- However, an oil-based anticorrosion agent is sensitive to touch and can be wiped away during handling, leaving unprotected areas more likely to rust.

- Oil-based mold protectants produce oil marks on transparent and optical parts if the mold is not properly cleaned before production restart.

Wax-based mold protectants:

- Wax-based mold protectants provide a consistent and longlasting protective layer and do not creep. Also, the wax-based protection film covering the surface of the tool remains intact even if swept over with a finger.

- Wax-based anticorrosion agents protect surfaces considerably longer than oil-based agents because they form an even and dry protection film on the surface without any dripping or creeping that cannot be wiped off by touching it.

- Wax-based mold protectants produce lower must emissions when applied, leading to a cleaner working environment.

- Also, wax-based anticorrosion agents are much easier to remove, since they melt at normal processing temperatures and are removed during the course of regular demolding. A separate cleaning procedure — as required by conventional oil-based products — is not necessary. This leads to a smoother and faster production process.

- However, in case the surface is not completely dry, waxbased anticorrosion agents may cover remaining moisture like a blanket, not allowing the moisture to evaporate or dry-off and thereby causing local corrosion. Therefore, it is highly important that the surface is dry before applying the wax-based anticorrosion agent.

We recommend to remove oil-based anticorrosion agents with a surface cleaner before the production process.

Wax-based mold protectants melt at normal mold temperatures and are removed from the mold in the course of regular processing. A separate cleaning procedure for wax-based anticorrosion agents is therefore not required.

Multifunctional sprays usually offer up to three months of temporary protection, whereas dedicated anticorrosion agents provide much longer protection times (12–24 months) and should be used when an extended storage period is expected.

Wax-based anticorrosion agents save time when restarting thermoplastic molding because the agent melts during the process and manual cleaning of the mold surface cavity is not required. In addition, a wax-based agent reduces scrap due to the fast absorption of the agent.

The number of cycles required depends upon multiple variables such as the mold design, operating temperatures, process, etc. In general, just a few cycles are necessary to fully eliminate the wax-based mold protectant from the cavity surface.

Chem-Trend offers both oil-based and wax-based mold protectants.

For example, Lusin® Protect G 11 is an oil-based mold protectant, whereas Lusin® Protect G 31 is a wax-based anticorrosion mold protectant.

Yes.

Lusin® Protect O 45 F is a grease-based mold protectant that is NSF H1 registered. This mold protectant allows for medium long protection, as no corrosion was found after 50 hours of sales water spray test per DIN 50021.

Lusin® Protect G 31 F is a wax-based mold protectant that is NSF H1 registered and offers long-lasting protection, as no corrosion was found after 150 hours of sales water spray test per DIN 9227.

In thermoplastic processing, lubricants are mainly used to avoid seizing or blocking of moving parts such as ejector pins, sliders, nozzles, and conveyor belts.

Often, low-quality or non-specialized lubricants are thermally unstable. The film created by such lubricants can “come off” the ejector pins and reach the tips of the pins. From there the lubricating film can be transferred to the parts ending up as a deposit on the demolded part.

Thermally stable, special purpose lubricants are specifically developed for ejector pin applications and are designed to remain on the ejector pins with no risk of being transferred during processing.

The lasting effect of a lubricant depends mainly on the type of lubricant, the application and the tool cycle time. Results will vary based upon these parameters. It is best to select a lubricant designed specifically for the purpose and temperature range required.

Lusin® Lub PZO 152 is specially designed for general industrial use and Lusin® LU1201F has been developed specifically for food packaging applications. Both lubricants operate at temperatures of up to 150°C (300°F).

Lusin® lubricants are available as aerosols or in tubes or cans, depending on the particular product.

Lusin® PM 1001 will continue to provide the lubrication and anti-seize properties that the product was designed to deliver despite it drying at high temperatures.

Lusin® products meet the highest quality standards. They are economical, easy to use, and have a high benefit/cost ratio. In addition, by using all available product groups, synergies can be realized that provide additional benefits not evident when only one product group is used.

Lusin® products can be distinguished by the nomenclature and color coding on the aerosol cans:

- Lusin® Alro = release agents

- Lusin® Lub = lubricants

- Lusin® Protect = protective agents

- Lusin® Clean = cleaning agents

Applying a stained or pigmented mold protectant is much easier as the anticorrosion agent is more visible on the surface, allowing for higher precision in applying an even film while producing less waste.

Apart from a few exceptions, Lusin® products have a shelf life of two years. Limitations concerning the durability of each product are covered in the product information leaflet.

The limiting durability factor is not the active agent in the Lusin® product, but the guarantee on the seal of the aerosol can, which the manufacturer limits at 24 months. Therefore, to assure product quality and integrity, we limit the shelf life to stay within the safe limit life of the aerosol can.

Yes, Lusin® products are developed to work in conjunction with each other, and use of the full range of Lusin® products will provide additional synergies that enhance their valuable benefits.

Yes, due to Chem-Trend’s global network of production plants, sales offices, and distribution partners, Lusin® products are available globally.

Chem-Trend has a longstanding reputation as a leader in the areas of Health, Safety, and Environment (HSE). And, as part of the Freudenberg Group, the company has a strong set of established internal standards regarding quality, environmental protection, and occupational health and safety to guide it. This history, and continually monitored standards, motivates Chem-Trend to observe regulations that go far beyond local legal requirements.

Yes, Chem-Trend has a complete range of Lusin® products with NSF registration in various categories.

Detailed processing instructions and safety regulations relative to each specific product are included in the product information leaflets and the applicable product’s MSDS.

Disposal of product containers needs to be in compliance with local legislation. For details, please look at the MSDS relevant for your specific product and location.

Storage instructions for each specific product are provided in the product information leaflets and the MSDS for the relevant product.