Reduced waste. Increased performance in footwear manufacturing.

WHAT WE ACHIEVED.

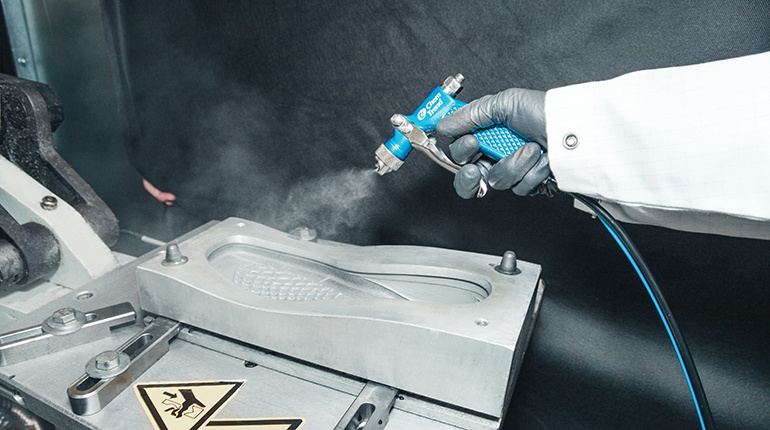

A manufacturer of occupational and safety footwear, running six modern production lines with an output of over one million shoes per year, was seeking a significant change. Aiming to improve the health, safety, and environment (HSE) impact of their operation without sacrificing performance, they sought to change their current solvent-based polyurethane sole molding process and reduce scrap rate with a water-based solution. Chem-Trend partnered with the customer to help them make the switch. The result netted in a 20% reduction in total release agent used, fewer hours spent on cleaning, and a dramatic decrease in scrap rate, leveling out at approximately 75% less than tested competitor water-based products. Additionally, with the switch to Chem-Trend’s water-based solution, the customer saw improved product appearance and a measured 33% increase in bondability between midsole and outsole, contributing to improved product durability.

HOW WE GOT THERE.

After consulting with the customer to understand their application parameters, we teamed up to conduct a comprehensive industrial trial. Three suitable water-based release agents were formulated and tested in the production environment to fine tune the highest-performing option. Along with improved HSE factors, requirements for success included improved release with less build-up and ensuring that the mold release agent did not interfere with the sole adhesion process and cause delamination (peeling strength between midsole and outsole required at least 60 N/cm). It quickly became clear that a finely balanced combination of parting agents and additives could provide efficient release ease. Throughout the trialing process, we were able to optimize the solid content within the final formulations, surpass the application requirements, and validate the results through the production of more than 7,000 shoes.

OUR SOLUTION.

The winning water-based solution met all performance criteria, including improved uniform and depth of matte surface appearance and quicker blast cleaning. With Chem-Trend’s release agent, the customer surpassed the minimum threshold, achieving 80 N/cm peeling strength between sole layers and is even using less release agent within the overall process. Providing better workplace safety to their employees as well as offering their end customer a product that’s made in a more sustainable way was ultimately achievable with the new water-based solution.

DATA INSIGHTS

20% REDUCTION IN TOTAL RELEASE AGENT USAGE

20% REDUCTION IN TOTAL RELEASE AGENT USAGE 33% IMPROVED BONDABILITY BETWEEN MIDSOLE & OUTSOLE FOR A MORE DURABLE SHOE

33% IMPROVED BONDABILITY BETWEEN MIDSOLE & OUTSOLE FOR A MORE DURABLE SHOE 75% LOWER SCRAP RATE THAN TESTED COMPETITOR WATER-BASED PRODUCTS

75% LOWER SCRAP RATE THAN TESTED COMPETITOR WATER-BASED PRODUCTSHANDPRINT IMPACT

At Chem-Trend, we pride ourselves on our long history of sustainability efforts. However, it is our effect on our customers’ processes that provides the greatest impact. It goes beyond our global Footprint; it is our even wider Handprint.

Here, we achieved the following:

- Reduced VOCs emitted during production.

- Lower overall product usage throughout process.

- Less material waste than solvent-based solution.

Materials

Waste

Emissions