Better process. Superior result.

WHAT WE ACHIEVED.

Chem-Trend is aggressively focused on helping our clients achieve exceptional outcomes. This is carried out in multiple ways:

- Helping produce a better product initially

- Helping produce a better product over time

- Extending the life of molds and equipment

- Improving cycle times and cleaning needs/maintenance

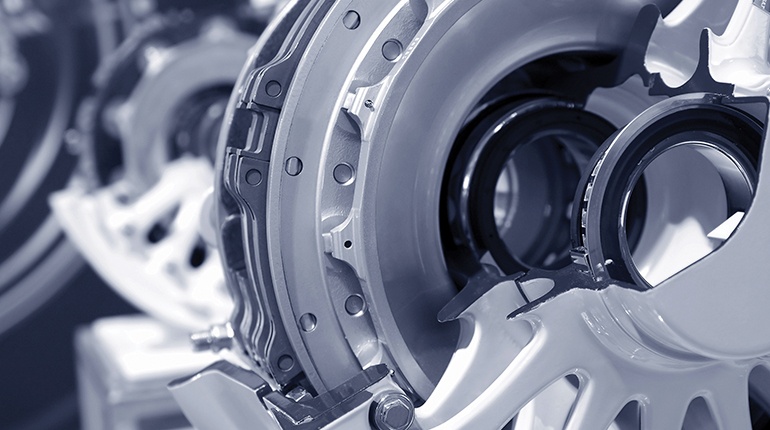

Through a hands-on process with collaborative testing, we were able to solve all of our aggressive goals with a manufacturer of automotive clutches.

HOW WE GOT THERE.

Working with an automotive parts manufacturer in Asia, Chem-Trend team members were able to analyze current products, processes, and pain points. What we found was a product that, over time, created significant buildup.

This release product created issues ranging from difficult cleaning cycles to increased labor. Formulation of a new product required iterations before we were able to achieve an improved, repeatable, and sustainable result.

This game-changing water-based solution improves part quality, protects tooling investments, and maximizes operational productivity for customers.

Through Chem-Trend’s acquisition of Huron Technologies, additional product technology, manufacturing, and process know-how were combined with Chem-Trend’s breadth of release agent technologies. These shared assets enabled Chem-Trend’s engineers to accelerate the development of highly advanced products for the molding of friction components.

OUR SOLUTION.

This drastic difference is the result of our dedicated research and development teams that were able to produce a superior product. Not only does it achieve remarkable results, but it can do so with the potential of using less release agent per part produced. Chem-Trend is now positioned as the gold standard for the production of molded friction components, such as clutches and brakes.

DATA INSIGHTS

INCREASED PRODUCT QUALITY Better detail, more consistent result.

INCREASED PRODUCT QUALITY Better detail, more consistent result. REDUCED CLEANING CYCLES Allowing for higher productivity and efficiency.

REDUCED CLEANING CYCLES Allowing for higher productivity and efficiency.HANDPRINT IMPACT

At Chem-Trend, we pride ourselves on our long history of sustainability efforts. However, it is our effect on our customers’ processes that provides the greatest impact. It goes beyond our global Footprint; it is our even wider Handprint.

Here, we achieved the following:

- Reduced cleaning needs, leading to reduced waste

- Greater product quality, leading to reduced scrap rate

- Extending the life of molds requires fewer material needs over time

- Fewer cleanings and reduced need for new molds saves transportation and shipping needs

Materials

Waste

Energy